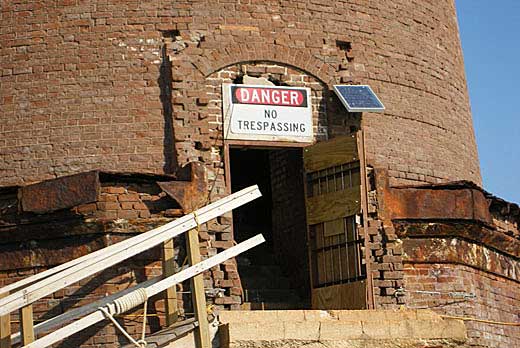

Family Life

The Davis Family

Insights into life as a lightkeeper are very interesting. Our opportunity to understand life on Morris Island is enhanced by the fact that several children of the last lightkeepers on the island have shared their pictures and stories with us.

See the Archive Article Living on Top of the World for another story.